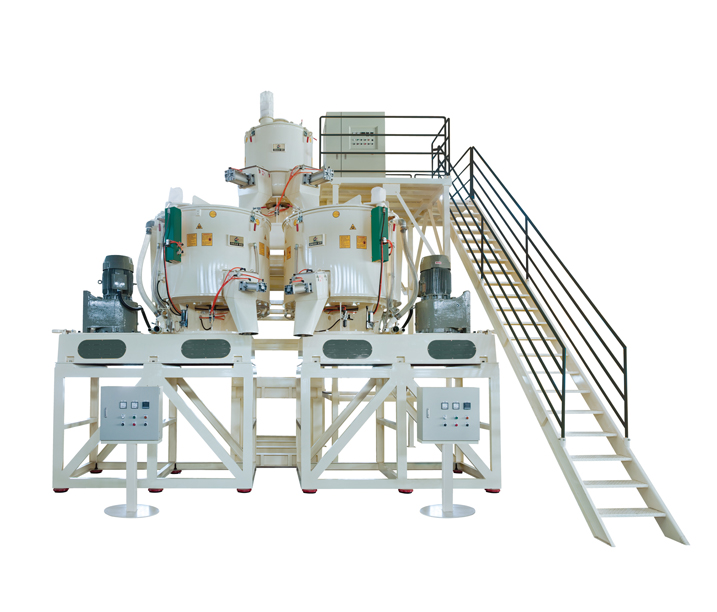

Specially designed two cooling blenders effectively shorten cooling time of mixed products.

The flow guide plate is a special design, featuring uniform mixing, high speed, superior dispersion and energy saving.

Exclusively designed material outlet port can be set according to customer’s material types. Another benefit is its fast material outfeed with residuals.(Patented design).

The mixing blade is designed with a cutting guide curve for extremely smooth material guide, while lowering electricity consumption. Partial blade is hardened for extending service life.

Special setting of machine: low noise.

The tank invertor is a stainless steel construction, polished to upgrade material missing efficiency and reduce electricity consumption.

The steel base is a one-piece fabrication and equipped with anti-vibration pads, providing smooth and stable running.